Partec Srl

Via Costa Erta, 21

24020 – Parre (BG)

P.iva 02657020166

Tel: +39 035-705800

Fax: +39 035-705820

Email: info@partec.it

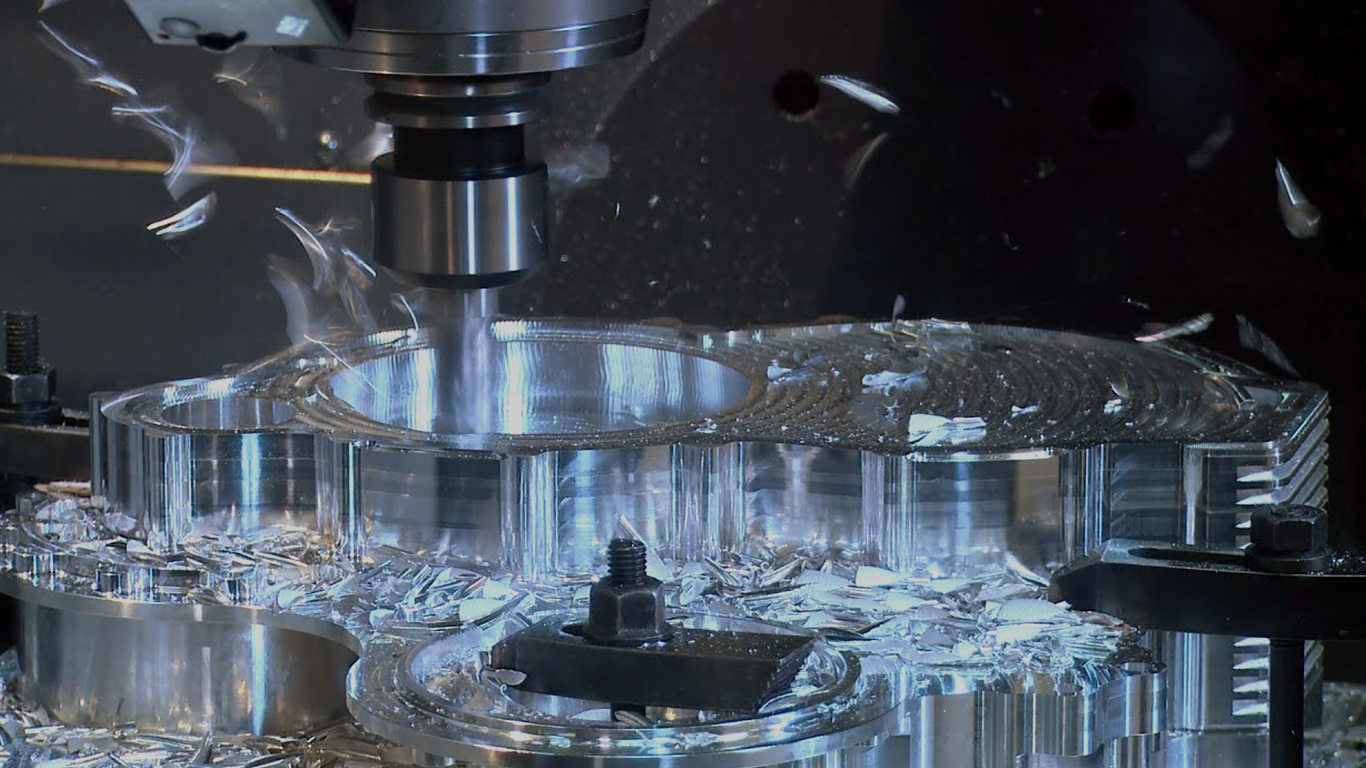

CNC (Computerized Numerical Control) is a system that coordinates the movements of a machine, so that a tool moves on predefined trajectories on specific axes: Partec apply this technologies to material milling processes.

This process permits to obtain plastic or metal pieces of excellent quality. The precesion is the best guaranteed compared to other technologies: the tolerance is ±0,1 mm.

Partec has many definitive materials both plastic and metallic: for example ABS, PMMA, PC, brass, aluminum and iron in different alloy.

|

Parts obtained from CNC, in addition to dimensional precision and excellent aesthetic result, can be refined after process as well as the pieces obtained with other technologies: the post-process are painting, plating and other superficial treatment similar to that used for pieces obtained by definitive mold.

A block of selected material is fixed inside the machine and milled: the piece is obtained by the removal of material from the block itself.

The milling, or in some cases turning, takes place following the surfaces of the 3D file provided by the customer.

What is obtained is a piece of great dimensional precision and mechanical characteristics close to those that a molded piece.