Partec Srl

Via Costa Erta, 21

24020 – Parre (BG)

P.iva 02657020166

Tel: +39 035-705800

Fax: +39 035-705820

Email: info@partec.it

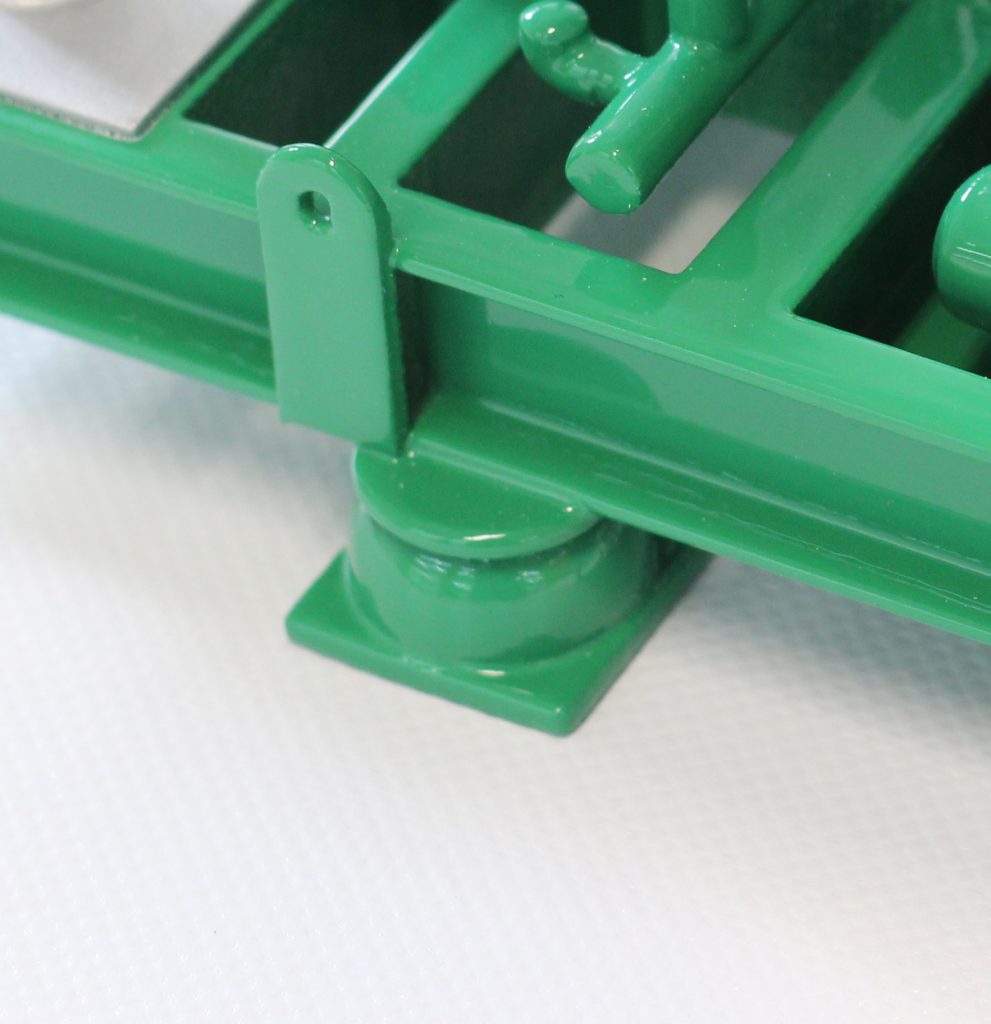

The SLS (Selective Laser Sintering) process is an additive technology which consists in the compaction and transformation, by a laser, of material from powder to solid. Through the sintering of nylon powder, Partec realizes details of good dimensional quality and remarkable mechanical characteristics. For this reason, this type of technology is the ideal solution for projects that need physical properties suitable for the assembling tests: the prototypes made of sintered material are integrated with good elasticity. A sintered model is suitable for various post-process machining, including drilling, threading holes and assembling by hooks (for example snap-fit).

The type of material used in sintering is also suitable for welding: an excellent post-production process to obtain large parts. Partec technicians designs the division of large components for better printing and the gained models could be reassembled with precision. However, through the finishing afetr the realization is possible to hide the joints of these details achieved in cut and welded parts.

|

Given the cost-effectiveness of the material, SLS is also a good solution for the production of small quantities of small-medium sized parts.

The properties of high temperatures resistance of nylon allow to have prototypes suitable for different tests or finishing processes (for example simil chrome plating) which are difficult to pursue with other materials.

Some types of materials used with this technology are declared hygroscopic, but sintering has surfaces that are not impervious perfectly to air or water: so that this defect is solved, Partec proposes, where necessary, a painting ad hoc of the details in order to make them waterproof.

A laser compacts the powder material (Nylon is the elementary material) all inside a tank from which a fine workmanship – once the job has cooled – extracted the sintered prototypes. The basic material, precisely in nylon, can be loaded in percentage with powder from other materials to improve the mechanical performance of the models obtainable: for example, glass or aluminum powder (Alumide) can be added. This technology is excellent for obtaining large parts: the division of large components for the best cutting in the machine is organized and the sintered material is suitable for welding; the joints on the larger parts can be hidden by grouting and sanding.